Are your operations teams constantly busy, yet delays, rework, and inefficiencies keep showing up? If you manage operations, this situation likely feels familiar. Work moves fast, tasks get completed, but accountability stays unclear, and real improvements take longer than expected.

A lot of operational inefficiencies come from unclear priorities and ownership, and not because of a lack of effort. While teams concentrate on task completion, they often overlook outcomes such as cycle time reduction, quality improvement, or cost control.

This is where many operations teams struggle. You track metrics, hold reviews, and push for efficiency, yet day-to-day execution does not always align with what the business actually needs to improve.

OKRs help shift that focus. Instead of measuring effort, they help you measure impact. With the right OKRs in place, your team can improve efficiency, clarify ownership, and stay accountable for outcomes that matter.

In this guide, you’ll find 10 practical OKR examples designed specifically for operations teams looking to improve efficiency and accountability without slowing down daily work.

At a Glance

- Operations teams often stay busy without improving efficiency or accountability.

- Most issues come from unclear ownership, task-based tracking, and late feedback.

- OKRs help shift focus from activity to measurable operational outcomes.

- Effective OKRs use existing metrics like cycle time, quality, and delivery reliability.

- Start with a small set of objectives and review progress regularly.

- When implemented well, OKRs improve execution without slowing down daily work.

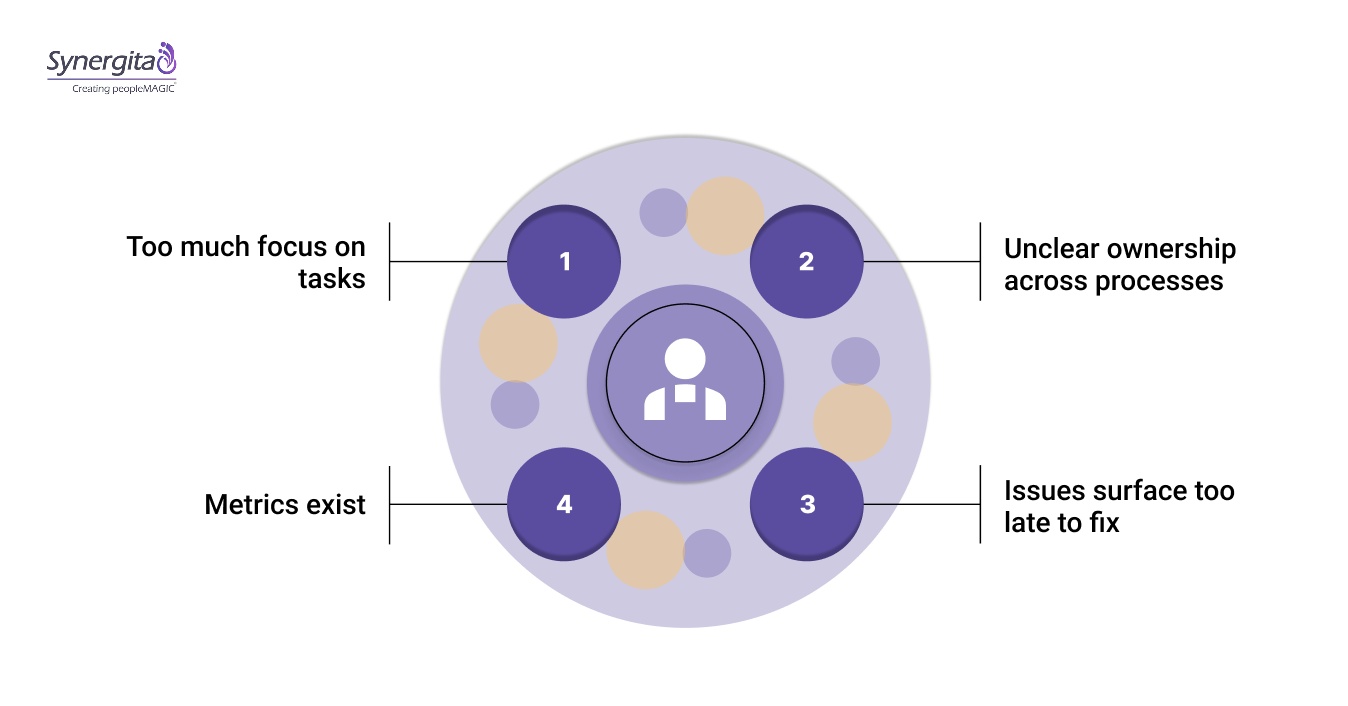

Why Operations Teams Struggle With Efficiency and Accountability?

Operations teams work hard to keep things running. Yet inefficiencies, delays, and repeated issues still show up. The challenge is rarely effort. It’s how work is prioritized, owned, and measured.

1. Too much focus on tasks instead of outcomes

You may track completed tickets, shifts covered, or processes followed. But these activities don’t always show whether operations are improving. When teams focus on tasks, problems repeat. Cycle times stay high, errors continue, and accountability feels unclear. The work gets done, but the results don’t improve.

2. Unclear ownership across processes

Operations often involve multiple teams, handoffs, and dependencies. When ownership is not clearly defined, issues fall between teams. You see delays, finger-pointing, and slow resolution times. Without clear accountability for outcomes, problems linger longer than they should.

3. Metrics exist, but are disconnected from goals

Most operations teams track plenty of metrics. However, these numbers often live in dashboards without a clear purpose. When metrics are not tied to improvement goals, teams review them without acting. Visibility exists, but direction does not.

4. Issues surface too late to fix

Many operational problems appear only after deadlines are missed or costs increase. By the time you review the data, the damage is already done. Without leading indicators tied to execution, teams react instead of adjusting. Efficiency suffers, and accountability turns into explanation rather than improvement.

Understanding these challenges makes it easier to see how a different goal-setting approach can improve execution.

Must Read: HR Analytics And Reporting: A Complete Guide

How Do OKRs Help Operations Teams Improve Execution?

OKRs give operations teams a simple way to move from busy work to real improvement. Instead of tracking everything, you focus on what must change and how success will be measured. Here is how OKRs for operations teams help boost execution.

1. Turn efficiency goals into measurable outcomes

Operations goals often sound vague, such as “improve efficiency” or “reduce delays.” OKRs force clarity. You define exactly what needs to improve, whether it’s cycle time, error rates, or on-time delivery. Clear outcomes help teams prioritize work that drives results, not just activity.

2. Establish clear ownership for results

OKRs assign ownership at the outcome level, not just at the task level. This removes confusion across shifts, teams, or processes. When ownership is clear, issues get resolved faster. Teams know what they are responsible for and how success is measured.

3. Align daily execution with business priorities

Operations teams handle urgent work every day. Without alignment, urgent tasks crowd out important improvements. OKRs help you connect daily execution to broader goals like cost reduction, quality improvement, or customer satisfaction. Teams can make better trade-offs when priorities are visible.

4. Identify risks early through regular check-ins

OKRs encourage frequent progress reviews. These check-ins highlight risks before they turn into delays or failures. Instead of reacting after problems occur, you can adjust processes, resources, or priorities in time. This shift from reactive to proactive execution improves reliability.

At this stage, many operations teams struggle to keep OKRs visible during day-to-day execution. Spreadsheets fade quickly once work begins. Tools like Synergita help teams track outcomes in real time and stay aligned without adding reporting overhead.

With this foundation in place, let’s look at practical OKR examples that operations teams can apply immediately.

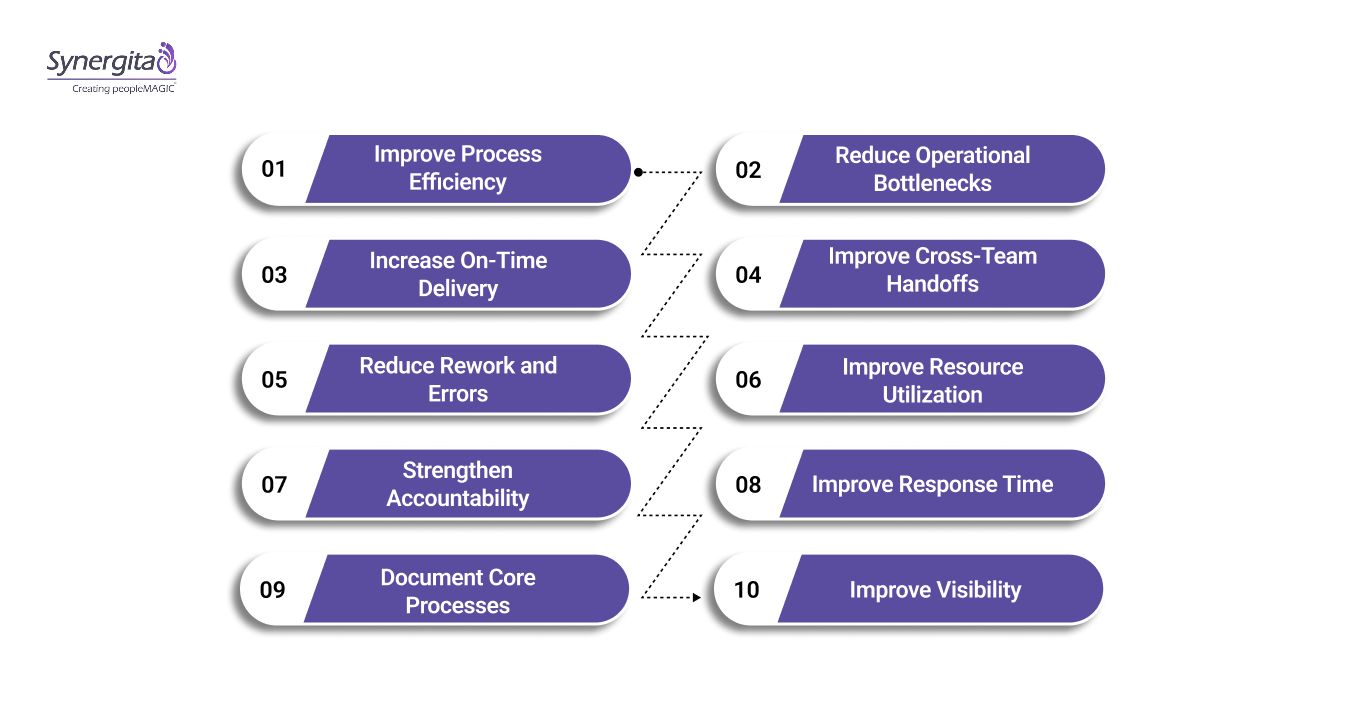

12 OKR Examples for Operations Teams

Each of the following examples focuses on outcomes that improve efficiency and accountability without adding complexity.

1. Improve Process Efficiency

Operations slow down when processes include unnecessary steps and repeated work. Efficiency improves only when teams focus on outcomes, not effort. This OKR helps you reduce cycle time and eliminate waste across core workflows. By setting measurable targets around speed and completion, your team prioritizes fixing broken processes instead of working around them. Over time, your organization creates faster, more predictable operations.

- Objective: Streamline core operational processes to reduce cycle time and waste.

- Key Result 1: Reduce average process cycle time by 20%

- Key Result 2: Eliminate at least 3 redundant steps from priority workflows

- Key Result 3: Increase first-pass completion rate to 90%

2. Reduce Operational Bottlenecks

Bottlenecks quietly drain productivity and delay outcomes. They often sit unnoticed until deadlines slip. This OKR focuses your team on identifying and removing constraints that limit flow. By tracking queue times and backlog levels, you can pinpoint where work slows down and fix it systematically. Removing bottlenecks improves throughput without increasing workload.

- Objective: Remove constraints that slow down operational flow.

- Key Result 1: Identify and document the top 5 recurring bottlenecks

- Key Result 2: Reduce average queue or wait time by 25%

- Key Result 3: Decrease backlog volume in critical workflows by 30%

3. Increase On-Time Delivery

Late delivery creates downstream problems across the business. Reliability matters as much as speed. This OKR improves execution discipline by focusing on delivery commitments. Measuring forecast accuracy and missed deadlines helps your team plan better and respond earlier to risks. As on-time delivery improves, trust with stakeholders increases.

- Objective: Improve reliability and consistency in operational delivery.

- Key Result 1: Achieve 95% on-time completion for committed deliverables

- Key Result 2: Reduce missed deadlines by 40%

- Key Result 3: Improve delivery forecast accuracy to 90%

4. Improve Cross-Team Handoffs

Most delays happen between teams, not within them. Unclear handoffs weaken accountability. This OKR clarifies ownership at every handoff point. By reducing wait times and rework between teams, operations move faster and with fewer escalations. Clear handoffs also reduce confusion and finger-pointing when issues arise.

- Objective: Reduce delays caused by unclear ownership between teams.

- Key Result 1: Define ownership and SLAs for 100% of cross-team handoffs

- Key Result 2: Reduce handoff wait time by 25%

- Key Result 3: Cut rework caused by handoff issues by 30%

5. Reduce Rework and Errors

Rework consumes time without adding value. Errors repeat when root causes stay hidden. This OKR shifts focus from fixing symptoms to preventing issues. Tracking rework rates and incident causes helps your team improve quality at the source. Over time, fewer errors lead to lower costs and smoother execution.

- Objective: Improve quality by preventing recurring operational issues.

- Key Result 1: Reduce rework rate by 30%

- Key Result 2: Identify root causes for 90% of reported incidents

- Key Result 3: Decrease repeat errors by 40%

6. Improve Resource Utilization

Underused or overworked resources signal poor planning. Balanced utilization improves both efficiency and morale. This OKR helps you align capacity with demand. By tracking utilization and overtime, your team can plan workloads more realistically. Better utilization reduces burnout while ensuring operational goals stay on track.

- Objective: Balance workloads to improve efficiency and team sustainability.

- Key Result 1: Maintain average utilization between 80–90%

- Key Result 2: Reduce overtime hours by 25%

- Key Result 3: Improve workload forecast accuracy to 90%

7. Strengthen Accountability Across Shifts or Teams

Issues often carry over when ownership is unclear. Shift changes should not reset responsibility. This OKR establishes clear accountability across teams and shifts. By defining ownership and improving handover resolution time, problems get addressed faster instead of being passed along. Accountability becomes visible and consistent.

- Objective: Ensure clear ownership and accountability across shifts and operational teams.

- Key Result 1: Define and document ownership for 100% of shift-based and cross-team workflows

- Key Result 2: Reduce unresolved handover issues between shifts by 40%

- Key Result 3: Resolve 90% of shift-related issues within the same business day

8. Improve Response Time to Operational Issues

Delays turn small issues into major disruptions. Fast response limits impact. This OKR focuses on speed and consistency in issue resolution. Tracking response times and repeat incidents helps your team act earlier and prevent escalation. Faster responses improve reliability and reduce operational stress.

- Objective: Reduce the time it takes to identify, respond to, and resolve operational issues.

- Key Result 1: Reduce average issue response time by 40%

- Key Result 2: Resolve 90% of operational issues within defined SLAs

- Key Result 3: Reduce repeat incidents caused by delayed response by 30%

9. Standardize and Document Core Processes

Inconsistent processes create unpredictable outcomes. Standardization enables scale. This OKR ensures critical processes are clearly defined and documented. When teams follow the same standards, quality improves, and onboarding becomes easier. Documentation also reduces dependency on individual knowledge.

- Objective: Create consistent, documented operational processes that scale across teams.

- Key Result 1: Document 100% of critical operational processes

- Key Result 2: Achieve 90% adherence to documented process standards

- Key Result 3: Reduce onboarding time for new team members by 25%

10. Improve Visibility Into Operational Performance

You can’t improve what you can’t see. Visibility drives better decisions. This OKR makes performance transparent and actionable. By focusing on a small set of meaningful metrics, your team spends less time reporting and more time improving. Clear visibility strengthens accountability at every level.

- Objective: Make operational performance visible, measurable, and actionable.

- Key Result 1: Define and track 5 core operational performance metrics

- Key Result 2: Publish weekly operational performance dashboards

- Key Result 3: Reduce time spent on manual reporting by 40%

11. Improve Cross-Functional Alignment

Operations break down when teams work toward conflicting priorities. Misalignment creates delays, rework, and escalations. This OKR ensures operations stay aligned with other departments by improving communication, shared planning, and visibility into priorities. Better alignment reduces friction and helps teams move faster together.

- Objective: Improve alignment between operations and cross-functional teams.

- Key Result 1: Publish shared operational priorities for all departments each quarter

- Key Result 2: Reduce cross-functional escalations caused by misalignment by 30%

- Key Result 3: Hold monthly cross-functional planning or review sessions

12. Strengthen Operational Planning and Forecasting

Poor planning leads to reactive execution and constant firefighting. This OKR improves predictability by strengthening operational planning and forecasting. With better forecasts, teams can allocate resources earlier, reduce last-minute changes, and execute with greater confidence.

- Objective: Improve the accuracy and reliability of operational planning.

- Key Result 1: Forecast operational demand within ±10% accuracy

- Key Result 2: Reduce last-minute plan changes by 30%

- Key Result 3: Document and review operational plans on a quarterly cadence

Having the right OKRs matters, but how teams implement them determines long-term success.

Must Read: What Every Manager Needs to Know About Setting Objectives

How Operations Teams Should Implement OKRs Without Slowing Work?

OKRs should support execution, not compete with it. When implementation feels heavy, operations teams lose momentum. The goal is to make OKRs part of daily work, not an extra layer on top of it.

1. Start with a small set of high-impact outcomes

Avoid the urge to cover everything. Focus on two or three operational outcomes that would make the biggest difference if improved, such as reducing delays, improving quality, or increasing reliability. Fewer objectives keep attention sharp and make it easier for your team to act decisively.

2. Use metrics your team already tracks

Operations teams already rely on trusted metrics like cycle time, error rates, throughput, and utilization. Use these as key results. When OKRs are built on familiar data, teams spend less time debating numbers and more time improving performance.

3. Fit OKR check-ins into existing routines

Do not introduce new meetings just to review OKRs. Instead, align updates with existing rhythms like daily stand-ups, shift handovers, or weekly operations reviews. Short, consistent check-ins help surface risks early without interrupting work.

Some teams use lightweight OKR platforms such as Synergita to bring progress updates into existing stand-ups or operations reviews instead of creating separate tracking processes.

4. Assign clear ownership for each objective

Every objective needs a clear owner, even when multiple teams contribute. Ownership means responsibility for progress and outcomes, not doing all the work alone.

Clear ownership prevents delays and ensures issues don’t get passed between teams or shifts.

5. Treat OKRs as a learning tool

When progress stalls, use OKRs to understand what’s blocking execution. Focus on what needs to change rather than who is at fault. This approach keeps teams honest, adaptive, and focused on improvement instead of defensive reporting.

Even with a solid implementation approach, certain mistakes can limit the impact of OKRs.

Must Read: How to Set Effective OKRs for Startups: Examples & Strategies

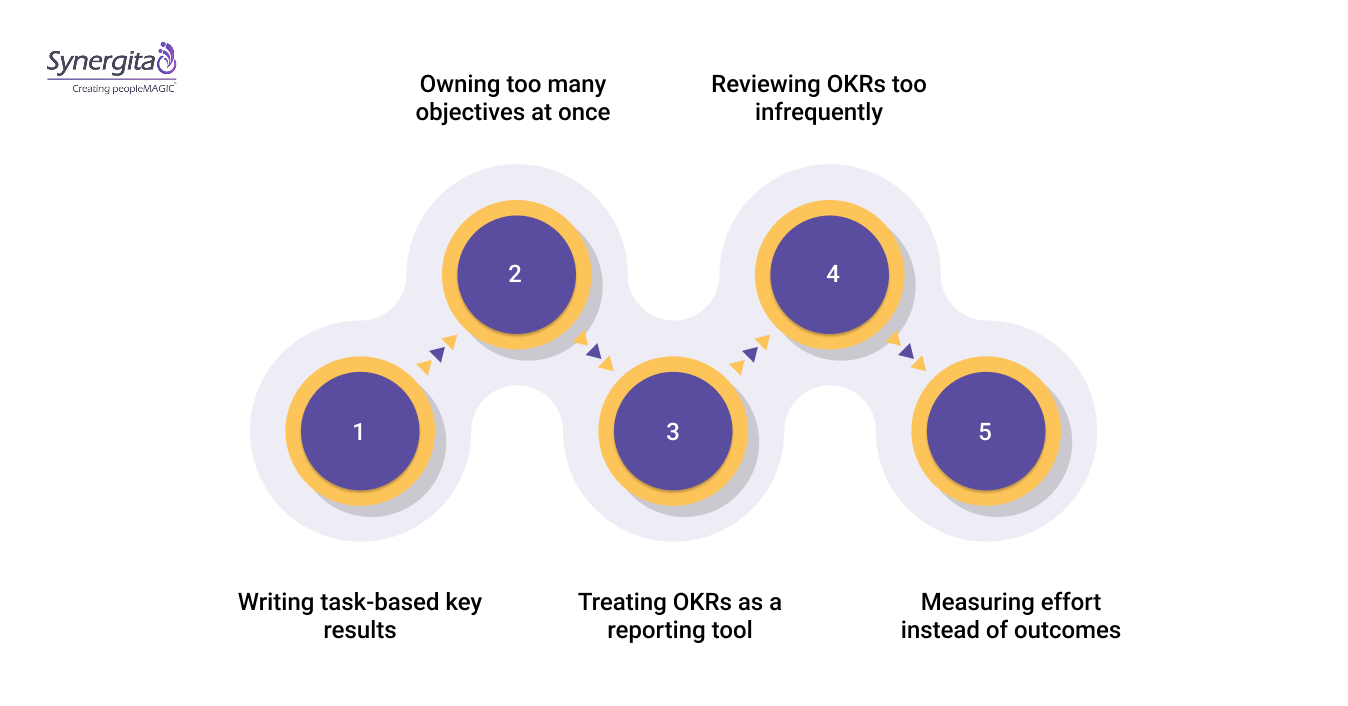

Common Mistakes Operations Teams Make With OKRs

OKRs fail in operations when they add friction instead of clarity. Most issues come from how teams apply OKRs, not from the framework itself.

1. Writing task-based key results

It’s easy to turn OKRs into task lists. Key results like “complete process review” or “run training sessions” track activity, not impact.

When key results don’t measure outcomes, you can’t tell whether operations are improving. Focus on measurable change, such as reduced cycle time, fewer errors, or faster resolution.

2. Owning too many objectives at once

Operations teams often juggle multiple priorities. Adding too many OKRs spreads attention thin.

When you limit objectives to what truly matters, teams stay focused, and execution improves. Fewer goals create clearer accountability.

3. Treating OKRs as a reporting tool

Some teams update OKRs only for leadership reviews. This turns OKRs into paperwork.

OKRs should guide daily decisions. If reviews happen only at the end of the quarter, problems surface too late to fix.

4. Reviewing OKRs too infrequently

Quarter-end reviews defeat the purpose of OKRs. Operations move too fast for delayed feedback.

Short, regular check-ins help you catch risks early and adjust before delays or quality issues escalate.

5. Measuring effort instead of outcomes

Tracking hours worked, tickets closed, or shifts covered creates a false sense of progress.

Operations teams need key results tied to results such as reliability, efficiency, cost control, and quality. Outcomes drive accountability. Effort does not.

Must Read: Continuous Feedback Culture: 6 Strategies to Motivate, Develop, and Retain Talent

Avoiding these pitfalls helps operations teams get lasting value from OKRs.

Conclusion

Operations teams succeed when work leads to visible improvement, not just completed tasks. Efficiency, accountability, and reliability improve only when teams know what must change and how success is measured.

OKRs help operations teams shift focus from effort to outcomes. Clear objectives, defined ownership, and regular reviews of progress make execution more predictable. Teams spend less time reacting to issues and more time improving how work gets done.

The key is keeping OKRs practical. Start small, use existing metrics, and review progress often. When implemented this way, OKRs support daily operations instead of slowing them down and help teams deliver consistent, measurable results over time.

Teams looking to operationalize OKRs without slowing down daily work often rely on tools like Synergita to connect goals, ownership, and progress in one place. Book a demo today!

FAQs

1. How are OKRs different from operational KPIs?

KPIs track ongoing performance such as throughput, defect rates, or downtime. OKRs focus on what needs to improve over a specific period. You use KPIs to monitor stability and OKRs to drive change. Together, they help operations teams maintain performance while improving weak areas.

2. Should frontline operations teams use OKRs?

Yes. OKRs work best when they are owned close to execution. Frontline teams understand where delays, waste, and quality issues occur. Keep OKRs simple and outcome-focused. Avoid adding extra reporting or complex scoring for frontline teams.

3. How often should operations teams review OKRs?

Weekly or bi-weekly reviews work well for most operations teams. These check-ins help you spot risks early and adjust priorities before issues escalate. Avoid waiting until the end of the quarter. OKRs lose value when feedback arrives too late.

4. Can OKRs work in shift-based or 24/7 operations?

Yes. OKRs work well in shift-based environments when ownership and handovers are clear. Assign owners for each objective and review progress during shift transitions or daily operational reviews. This keeps accountability consistent across shifts.

5. What’s the biggest sign that OKRs are not working?

If work feels busy but results don’t improve, OKRs may be tracking activity instead of outcomes. Review your key results. If they measure tasks or effort, rewrite them to reflect efficiency, quality, or reliability improvements.