82% of leaders say they struggle to balance short-term operational demands with long-term strategic change across complex supply chain teams. That tension shows up as missed handoffs, conflicting priorities, and constant firefighting that drains confidence from executives and frontline managers alike.

If you lead operations, you feel this pressure daily while teams chase local goals that quietly work against company direction. You are asked to cut costs, protect service levels, and prepare for disruption, all without clear shared priorities across functions.

In this blog, we explore how OKRs for operations give leaders a practical way to set shared outcomes and achieve alignment across supply chain teams. You will learn core use cases, ten examples, writing guidance, coordination methods, and common leadership mistakes to avoid.

Key Takeaways:

- Supply chain teams fail at handoffs when goals stay local, even when individual functions perform well against their own targets.

- OKRs give operations leaders a clear structure to define shared outcomes across procurement, manufacturing, logistics, and fulfillment teams.

- Strong OKRs focus on measurable results, assign one clear owner, and receive frequent reviews to surface risks early.

- Cross-team OKRs reduce finger-pointing by making joint outcomes visible and reviewed by all responsible leaders together.

- Consistent tools and review rhythms help leaders track progress, correct course early, and maintain confidence without constant intervention.

How OKRs Drive Alignment Across Supply Chain Operations

Supply chain performance breaks down when teams chase separate targets while leadership expects shared outcomes across procurement, production, and delivery. OKRs create a single direction for operations leaders who need consistent decisions across functions without adding extra process layers.

Here are the core ways OKRs change how supply chain teams plan, decide, and execute together:

- End-to-End Supply Chain Direction

OKRs set shared outcomes that connect procurement, manufacturing, logistics, and fulfillment around the same business priorities. Teams stop optimizing for local wins and start making decisions that support the full flow from suppliers to customers.

- Clear Tradeoffs Across Cost, Speed, and Quality

OKRs force teams to discuss tradeoffs openly instead of hiding conflicts inside functional targets and isolated metrics. Leaders gain visibility into what teams prioritize when cost, service, and reliability compete for attention.

- Shared Ownership Across Functions

Cross-functional OKRs assign responsibility for outcomes that no single team controls alone. This structure reduces finger-pointing and encourages joint problem-solving when delays or constraints appear.

- Executive Visibility Without Micromanagement

OKRs give leaders a consistent view of progress through outcomes rather than task updates and status meetings. Executives can course-correct early while teams retain control over how work gets done.

Theory only goes so far, so reviewing practical OKR examples helps you see how leaders apply these ideas across teams.

10 High-Impact OKR Examples for Supply Chain Teams

Clear examples help teams understand what good looks like and prevent OKRs from turning into vague statements that fail during execution. These examples focus on outcomes leaders care about and pressures supply chain teams face across planning, production, and delivery.

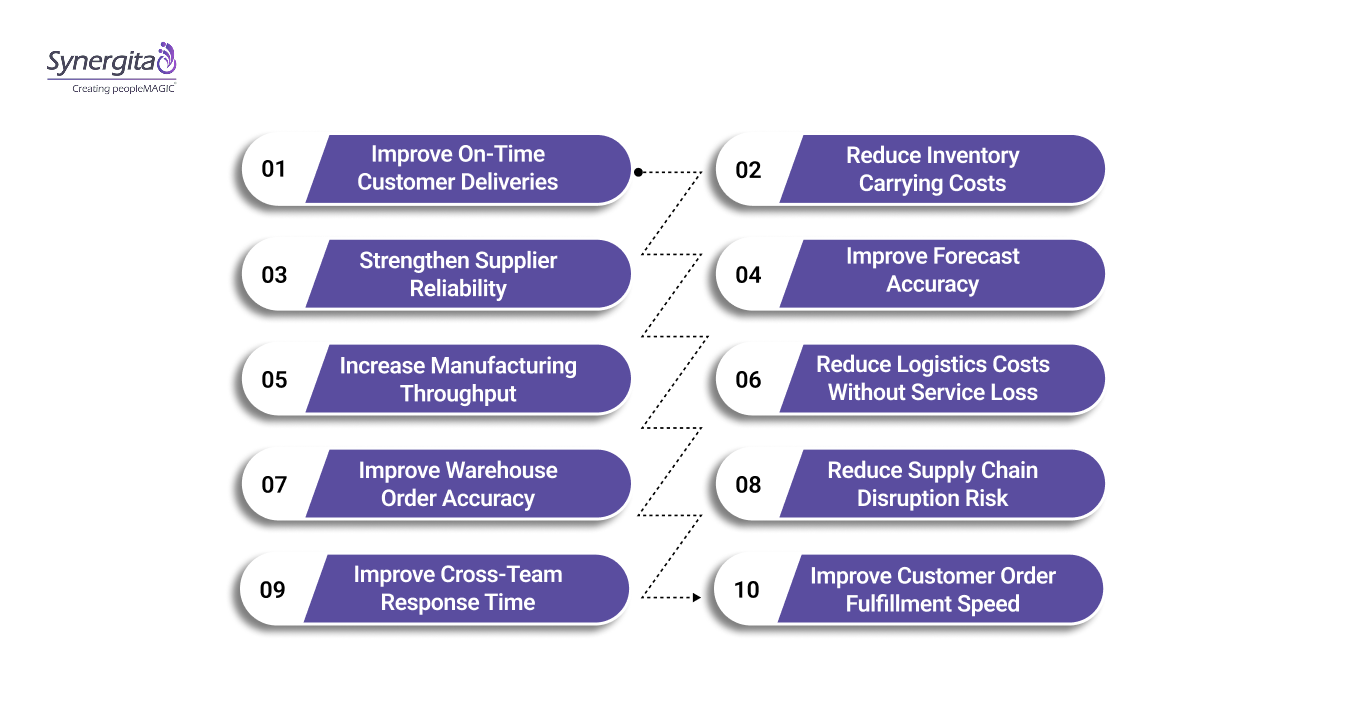

Here are ten OKR examples that operations leaders can adapt across supply chain teams without creating confusion or local goal conflicts:

1. Improve On-Time Customer Deliveries

Objective: Increase the reliability of customer deliveries across all regions.

Key Results: Raise the on-time delivery rate from ninety percent to ninety-seven percent while reducing late shipment escalations by thirty percent.

2. Reduce Inventory Carrying Costs

Objective: Lower excess inventory without increasing stockout risk.

Key Results: Decrease average inventory days by fifteen percent while maintaining service levels above agreed customer thresholds.

3. Strengthen Supplier Reliability

Objective: Improve consistency across critical suppliers.

Key Results: Increase supplier on-time inbound deliveries to ninety-five percent and reduce quality-related rejections by twenty percent.

4. Improve Forecast Accuracy

Objective: Increase planning accuracy across demand and supply teams.

Key Results: Improve forecast accuracy from seventy percent to eighty-five percent while reducing emergency production changes each month.

5. Increase Manufacturing Throughput

Objective: Improve output predictability across production lines.

Key Results: Increase average weekly throughput by twelve percent while holding defect rates within approved quality limits.

6. Reduce Logistics Costs Without Service Loss

Objective: Control transportation spend while protecting customer experience.

Key Results: Reduce logistics cost per unit by ten percent without reducing delivery speed commitments.

7. Improve Warehouse Order Accuracy

Objective: Reduce fulfillment errors across distribution centers.

Key Results: Increase order accuracy to ninety-nine percent while cutting customer complaints related to picking errors by half.

8. Reduce Supply Chain Disruption Risk

Objective: Improve readiness for supplier and transportation disruptions.

Key Results: Identify backup suppliers for the top twenty critical materials and test contingency plans through quarterly scenario reviews.

9. Improve Cross-Team Response Time

Objective: Speed up issue resolution across procurement, production, and logistics.

Key Results: Reduce average response time for cross-team issues from five days to two days.

10. Improve Customer Order Fulfillment Speed

Objective: Reduce the delivery cycle time.

Key Results: Cut average fulfillment cycle time by twenty percent while maintaining promised delivery dates.

To replicate these results, you need a consistent approach to writing OKRs that teams understand and leaders can inspect.

How to Write OKRs Without Creating Confusion

Writing strong OKRs for operations starts by clarifying what outcomes matter most across supply chain teams facing daily tradeoff decisions. Poorly written OKRs create confusion, slow decisions, and invite local targets that quietly work against company priorities.

Use the following principles to write OKRs that guide action, support leadership visibility, and keep teams focused on shared results:

- Start with business outcomes: Define success in terms that leaders recognize, not activities teams complete or reports they submit.

- Limit objectives per team: Cap each team at two objectives to protect focus and prevent priority dilution.

- Write measurable key results: Describe observable change in cost, time, quality, or reliability within a fixed period.

- Assign one accountable owner: Name a single leader responsible for progress, decisions, and tradeoffs when constraints appear.

- Set a clear review rhythm: Review progress weekly to surface risks early and adjust priorities before delays compound.

After writing clear OKRs, the next challenge is ensuring they work together across procurement, production, and logistics.

How to Align OKRs Across Supply Chain Teams

Supply chain teams fall out of sync when objectives stop at functional borders and shared outcomes lack clear ownership. Cross-team OKRs connect decisions across procurement, manufacturing, and logistics while giving leaders a clear view of progress.

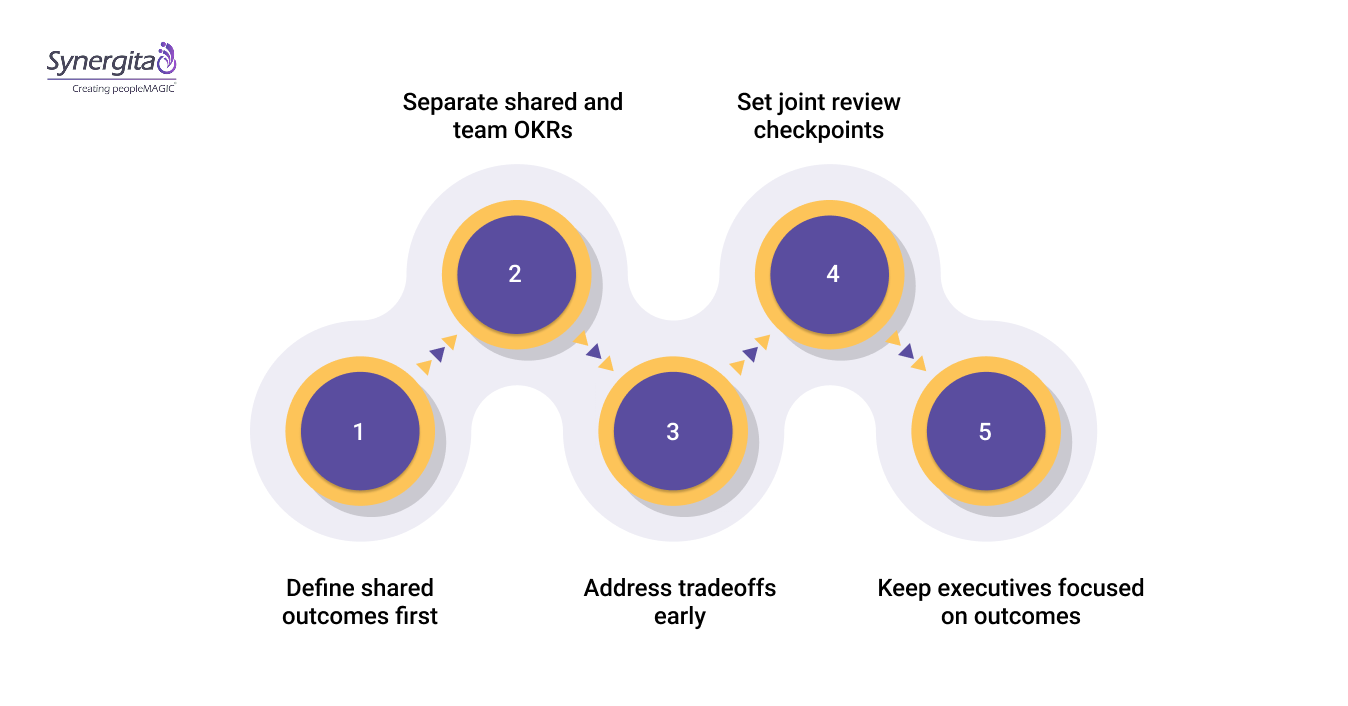

Use these practices to connect OKRs across teams without adding layers of coordination or slowing execution:

- Define shared outcomes first: Start with outcomes that require multiple teams to succeed, such as delivery reliability or response time reductions.

- Separate shared and team OKRs: Use shared OKRs for cross-team results, then support them with focused team-level OKRs.

- Address tradeoffs early: Discuss cost, speed, and quality conflicts during planning instead of letting teams resolve them independently later.

- Set joint review checkpoints: Review shared OKRs with all owners present to surface risks and agree on corrective actions together.

- Keep executives focused on outcomes: Leaders should review progress through results achieved, not task updates or detailed execution steps.

To sustain cross-team focus, leaders rely on tools and practices that support visibility, ownership, and regular inspection.

Tools and Techniques to Support OKR Execution

Strong OKRs fail when teams lack visibility, consistent reviews, and shared systems to track progress across supply chain functions. The right tools and practices help leaders monitor outcomes, surface risks early, and keep teams focused without relying on manual updates.

Here are practical tools and techniques that support OKR execution across operations teams:

- Centralized OKR tracking tools: Use a single system, such as Synergita, to track objectives, key results, ownership, and progress across teams.

- Outcome-focused dashboards: Provide leaders with clear views of results achieved, risks flagged, and trends emerging across supply chain functions.

- Regular progress check-ins: Schedule weekly reviews focused on movement in key results rather than task completion or status explanations.

- Automated reminders and nudges: Use reminders to prompt updates and reviews, reducing reliance on managers chasing teams for progress reports.

- Integration with daily work tools: Connect OKRs with tools teams already use, ensuring updates reflect actual work without duplicate reporting.

With the right practices and tools in place, OKRs become a steady guide for daily decisions across supply chain teams.

Conclusion

Supply chain leaders face daily pressure when teams move fast without shared outcomes guiding decisions across procurement, production, and delivery. OKRs for operations give leaders a clear way to set priorities, surface tradeoffs early, and keep teams focused on results that matter most.

When OKRs are visible, reviewed often, and owned by the right leaders, organizations achieve alignment across supply chain teams instead of working in silos. This shift reduces friction, improves predictability, and gives executives confidence without relying on constant intervention.

Start your free trial and turn misalignment into clarity with Synergita.

FAQs

1. What is alignment in supply chain management?

Alignment in supply chain management means teams across sourcing, production, and delivery work toward shared business outcomes rather than isolated functional targets. It ensures decisions made by one team do not create delays, cost increases, or service issues for another team downstream.

2. What are the 5 P’s of supply chain management?

The five Ps typically refer to Plan, Procure, Produce, Place, and Perform. Together, they describe how organizations plan demand, source materials, manufacture goods, distribute products, and measure results.

3. What are the three main areas of operations and supply chain management?

The three main areas are planning, execution, and control. Planning covers forecasting and capacity decisions, execution focuses on sourcing, production, and delivery, while control monitors performance and risk.

4. How long does it take to see results after introducing OKRs in operations?

Most teams begin seeing clearer priorities and faster decision-making within one quarter. More consistent delivery and cost outcomes usually follow after two to three review cycles.

5. Can OKRs work in supply chains with frequent disruptions?

Yes, OKRs help teams stay focused on outcomes even when plans change unexpectedly. They give leaders a structured way to reset priorities without rewriting every operational plan.